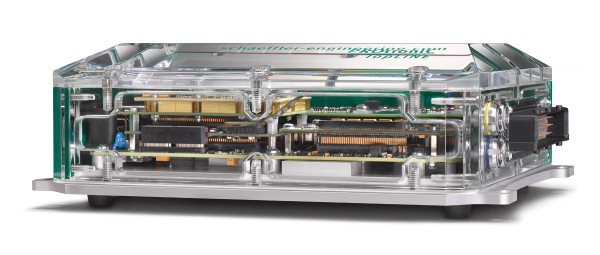

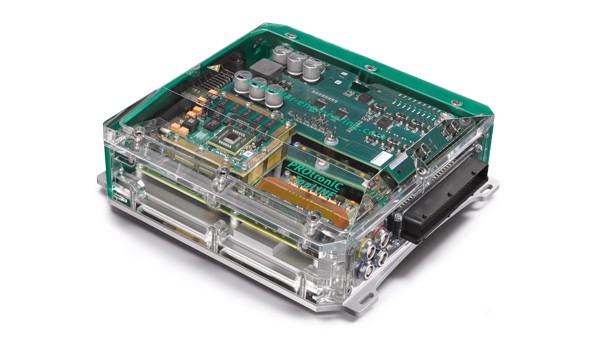

High performance and flexibility for protoyping

The PROtroniC TopLINE functions as an engine, transmission or vehicle control unit. It offers the degrees of freedom and computing power of a development control unit. The development results can be reused later in series production.

Seamless from prototyping phase to series production development

The PROtroniC TopLINE significantly accelerates the development of mechatronic systems. Long before the production ECU is available, new solutions can be tested and secured quickly and easily with the flexibly adaptable prototyping control unit.

Customers work with a model-based tool-chain that is also suitable for series development — thus creating a seamless transition from the prototyping phase to series development and getting ideas quicker on the road.

4 good reasons for the PROtroniC TopLINE

The PROtroniC TopLINE convinces with internal and external values that provide developers with clear benefits for their daily work.

1. Integrated power stage outputs and signal conditioning

- For all versions of the PROtroniC TopLINE

2. Customized HW / SW solutions for specific applications

- State-of-the-art FPGA technology for a software-based, quick, and easy configuration of the I/Os according to the specific applications with a Windows™‑tool

- Adjustment of the offered hardware modules for customer specific applications

3. "Safety on Board" concept to unite RCP and functional safety

- A multilevel monitoring concept for developing application-specific safety functions in the prototyping system

- Use of development tools that are approved for development according to ISO 26262

4. Seamless tool-chain from design to series production

- Development environment of the PROtroniC TopLINE based on tools used in the automobile industry for prototyping and series developments

- Supporting different code generators and different measurement as well as calibration tools

PROtroniC TopLINE as engine, transmission or universal control unit

For engine applications

This variant is designed for the development of classic combustion engines (gasoline, diesel, gas engines) as well as of alternative drives.

For transmission applications

Thanks to a VC module for the control of transmission valves, this variant is specially designed for transmission applications (classic or electrified).

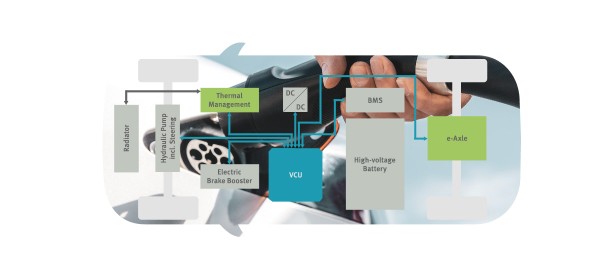

For vehicle applications

As a universal control unit, this variant can be used as a vehicle control unit (VCU), hybrid control unit (HCU) or chassis control unit (CCU).

High-performance in rapid control prototyping

Details of the PROtroniC TopLINE at a glance

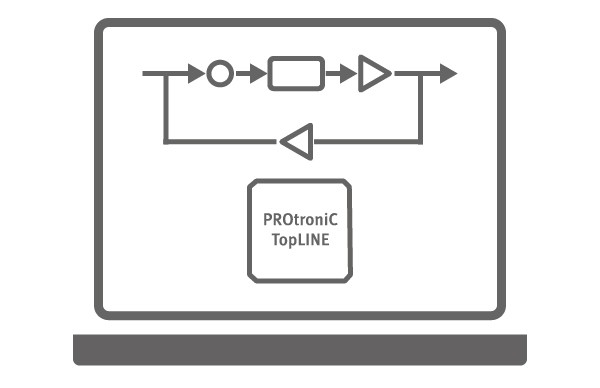

Seamless from design to production

In order to simplify the everyday work with the PROtroniC, its development environment is based on the widespread tools used in the automobile industry. In this way, developers not only have the possibility to freely select the code generator, but also the existing measurement and application tools.

1. Model-based function development

Graphic modeling of the control functions with

- MATLAB®

- Simulink®

- Stateflow®

2. Offline simulations

Testing and optimization of draft functions against a controlled system through offline simulations at the computer with

- MATLAB®

- Simulink®

- Stateflow®

3. Hardware mapping

A link between the inputs and outputs of the function model and the PROtroniC control unit via an application controller interface for

- MATLAB®

- Simulink®

4. Auto code generation

Automatic generation of efficient series codes and, if required, with

- TargetLink®

- Embedded Coder™

5. Validation

- Download of the generated software via the supplied boot loader

- Testing and verification of new functions on the test bench, in the vehicle or via hardware-in-the-loop simulation

6. Measurement & Application

Fine-tuning and measurement of the control software with

- MARC I

- INCA

- CANape

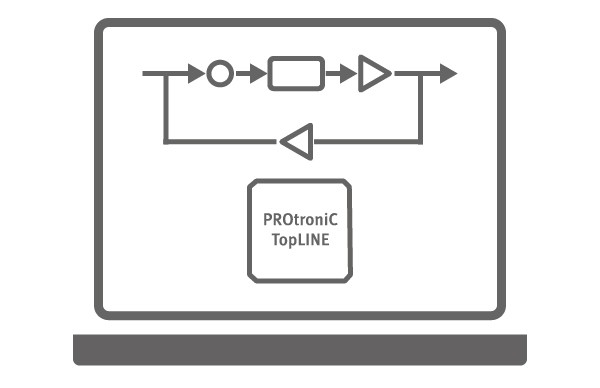

3-level monitoring concept for developing application-specific safety functions

The "Safety on Board" concept at a glance:

- A multi-stage monitoring system guarantees the realization of user-specific safety functions during prototyping

- Only development tools are used that are compatible with ISO 26262

- Enables the conception of safety-related functions in a model-based development environment

- Supports the realization of user-specific safety functions already during prototyping

- Helps to build an optimal system safety for fleet and road tests

- Offers one tool chain for everything – from prototyping to series production