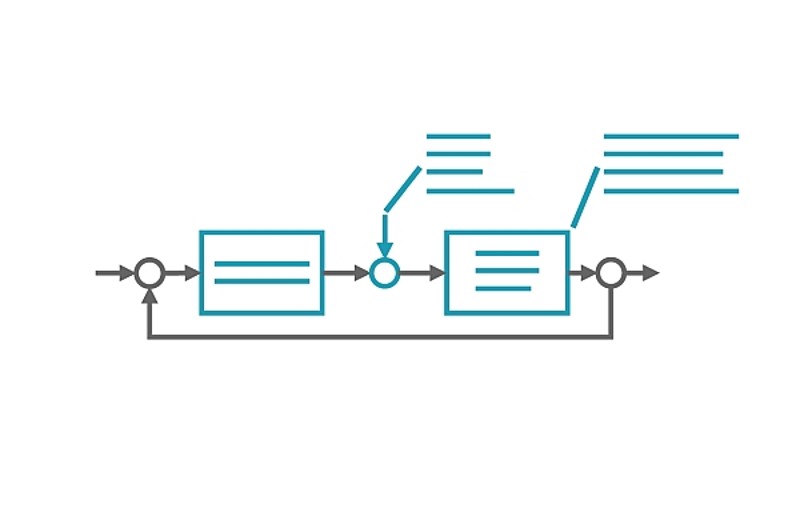

Controller Architecture

Suitable feedforward and feedback controller architectures are determined based on the com-plexity of the plant to be controlled, the requirements for the controlled system, and the availa-ble resources. We support our customers with this challenging task by offering comprehensive system and control skills.

Nothing works without a control unit. Invisible yet noticeable, they are omnipresent and a pre-requisite for our highly complex world. Their design always strives to achieve a balance between the requirements, properties of the plant, and available resources.

We got that under control for you!

This is where our experts for controller design come into play. They use an effective six-step process to accurately develop an appropriate controller based on the model of the plant. Our work and our development process are based on more than 40 years of system knowledge, experience, and project work completed for companies from different sectors.

Six steps to finding a suitable controller

We conduct the following six steps to develop a specific controller based on the requirements:

1. Definition and analysis of the control task

2. Definition, analysis and modeling of the plant to be controlled

3. Identification of the hardware properties (e.g. of control units/PLC, and sensors)

4. Systematic identification of a suitable controller architecture

5. Synthesis and implementation of the selected controller architecture

6. Commissioning, verification, and validation of the controlled system

The benefits speak for themselves:

1. Minimization of technical project risks – early plausibility checks of the control objectives and performance requirements (i.e., front loading of efforts even without an actual system).

2. Time-saving development from simple to highly complex control units – using parallel, model-based control unit synthesis and parametrization.

3. Achieving the required system performance – by analyzing the plant and requirements, and systematically identify the best possible architecture.

4. 4. Systematic and efficient options for system adjustments and modifications – thanks to control unit design and synthesis based on the plant model.