Mechanical Engineering

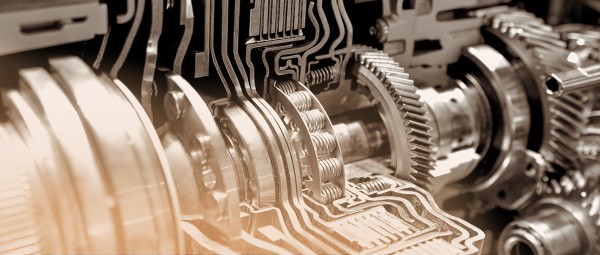

In the mechanical engineering sector, we offer a wide range of services relating to analysis, design, development and integration of drive units, transmissions, actuators and housings.

Overview

Mechatronic systems are found in all vehicles and form the basis of future-proof mobility concepts. They are also becoming increasingly important outside the automotive industry. However, whether in electric vehicles or collaborative robots (cobots), the seamless interaction between mechanics and electronics is always essential. And that is the point at which we take over.

The mechanical integration of electronics

Our extensive expertise in mechanical development makes us the ideal partner for mechatronic development projects. Electronic systems and their mechanical components are increasingly subjected to demanding requirements in terms of tightness, vibration endurance, thermal stability, etc. When motion becomes a factor, we develop your mechanical subsystem according to your special application.

Drive systems

High performance drives play a decisive role in e-mobility and in modern industry. The mechanical design of individual drive components and their interaction is challenging due to high power density, increasing speeds, maximum precision and the need for cost-effective manufacturability. Using our expertise in transmission, actuator and housing development, we provide the ideal solution for every application.

Mechanics, integration and simulation – we provide comprehensive solutions, as turn key solution

Given the prevailing high time and cost pressures, coupled with the increasing complexity of development, it is important to make the most of any potential for optimization, such as recruiting a partner for all your development work (by relying on one partner for all development tasks). As specialist in mechanics within the field of mechatronics, we possess the essential interdisciplinary expertise across multiple phases. Our interdisciplinary project teams enable us to efficiently address additional simulation and integration tasks in mechanical developments.

If you have any questions about our range of services in mechanical development, integration or simulation, please do not hesitate to contact us.

Mechanical design

Gearing design

- Transmission design from overall gear ratio to microgeometry optimization using KISSsoft software

- Gearing design and optimization with regard to lifetime, strength, friction and acoustics for metals and plastics

- Spur gears, ring gears, helical gears, planetary gear sets, special gears

Bearing design

- Development of bearing concepts for rotating systems using BearinX software

- Bearing design in terms of lifetime, strength, static safety, friction, temperature characteristics and lubrication

- Bearing design based on catalog roller bearings through to optimization of special bearings with individual geometries and configurations

Shaft design

- Definition of suitable shaft geometries in the context of gearing and bearing applications

- Shaft design per DIN 743, and FE-based shaft calculation

Cast design

- Design of complex cast aluminum components

- Optimization in terms of manufacturability, taking account of the requirements of the respective casting process, such as sand casting or die casting

- Maximization of stiffness and strength through appropriate ribbing using simulation methods such as structural optimization and finite element method (FEM) calculations

Installation space analysis

- Package inspection considerations from the concept phase to series production using PTC Creo CAD software

- Analyzing the installation situation for potential collisions and optimization for various mechanical and mechatronic product developments

- Consideration of manufacturing and assembly tolerances as well as temperature effects

Tolerance analysis

- Analysis of the impact of manufacturing tolerances on assembly feasibility and function

- Taking account of geometrical tolerances in tolerance chains

- Conducting statistical tolerance analyzes, taking into account different tolerance distributions for individual dimensions

Mechanical architecture

- Designing a mechanical system architecture from concept phase to start of production

- Definition of the mechanical system characteristics via requirements management using Windchill RV&S (Integrity) software

- Mechanical system design in the context of transmissions

Mechanical integration

- Integration of electrical and mechanical components in mechatronic systems, taking account of installation space, function, strength and lifetime

- Definition of suitable connection technologies and their design in accordance with the relevant requirements

Development of cooling & lubrication

- Design of active and passive liquid cooling systems using thermal simulations

- Development and analysis of lubrication structures using computational fluid dynamics (CFD)

- Development of lubrication strategies for transmission applications

Supplier management

- Managing from supplier selection through to production coordination for prototypes

- Sourcing and supplying the developed systems, ranging from functional samples to small production series

- Supporting the development of series suppliers taking into account the production capability

Product focus

Housing

- Development of housings, e.g. for electric motors, drive systems, actuators, control devices, inverters

- Integration and design of cooling structures for e-motor housings

- Definition of application-specific manufacturing processes

- Design of bolted joints and sealings using FEM calculations

Components related to electronics

- Mechanical integration of electronic components, such as printed circuit boards or electric motors, taking into account the specific requirements

- Definition and design of connection technologies for mounting electronic components

- Cabling with consideration of installation space requirements and specific product requirements

- Selection of suitable contacting and its integration into the housing context

Transmission

- Complete development of transmission gearing, starting from the concept phase through to series production readiness

- Design from the system level to the optimization of the individual components

- The development spectrum includes all required components, such as housings, bearings, gearing, seals and shafts as well as lubrication and cooling strategy

Actuators

- Development of high-ratio transmissions for various applications, ranging from cost-sensitive to highly specialized applications

- Integration of motor, electronics and transmission into an actuator system that fulfills the specified requirements